Have you ever bought a hydraulic hose crimper1 only to realize later it doesn’t suit your daily work? The wrong choice costs time, money, and productivity.

To choose the right hydraulic hose crimping machine, match it with your product range2, daily output needs3, budget, space limitations4, safety requirements5, and after-sales service availability.

When I help customers at CYT-HYDRAULIC, I always start by asking about their actual work needs. The machine must fit the work you do every day, not just the brochure specifications.

Why Is Choosing the Right Hose Crimping Machine So Important?

People often underestimate the impact of the crimping machine on their operations. A mismatch causes long delays and wasted resources.

Choosing the right hose crimping machine6 ensures proper compatibility with your hose and fittings, improves productivity, reduces downtime, and avoids unnecessary repair costs.

When you use the wrong machine, several problems can occur. A machine with limited opening diameter cannot handle your largest hoses. Underpowered crimpers may fail to compress hoses with multiple layers of steel wire reinforcement. Overpowered crimpers may damage small hoses or light-duty fittings.

A good match between machine capacity and your product list means you do the job faster, with fewer adjustments. This leads to consistent quality and fewer reworks. In my experience, customers who choose machines carefully have far less operational trouble.

The right machine also improves worker safety. A machine that struggles to perform can create accidents. Choosing properly calibrated models with correct force ranges keeps your team safe while maintaining performance.

What Factors Should You Consider Before Buying a Hose Crimper?

Buying a crimper is more than just picking a model from a catalog. You must look at your entire work process.

Consider the type of products, hose size range, daily crimping quantity7, compatibility with fittings, space limitations4, special standards, and your budget before buying a crimper.

Start with your product type. If you crimp hydraulic hoses, determine the minimum and maximum sizes and how many layers of reinforcement each hose has. If you crimp other products—like air-conditioning pipes, brake hoses, steel tubes, or terminals—write down the key dimensions before and after crimping, crimping length, material hardness, and any appearance requirements.

Estimate your daily output. Machines designed for high production can handle hundreds of crimps a day with minimal wear. Small manual models suit occasional use but won’t survive continuous demand.

Check compatibility between hoses, fittings, and machine specifications. Mismatch here is one of the most common rookie mistakes.

Think about your workspace. In tight spaces, compact or portable models work best. Safety certifications (CE, ISO) may be required depending on your site regulations. Features such as emergency stop buttons may be mandatory.

Budget matters, but buying cheap can cost more later. If possible, invest in higher-configuration models with imported core parts. Repairs and part replacements will be easier, which saves downtime.

What Types of Hydraulic Hose Crimpers Are Available?

Different work environments demand different machine designs. The right type depends entirely on how and where you work.

The main types are manual crimpers8 for low output and portability, and electric crimpers9 for high-volume workshop use, with variations such as semi-automatic, automatic, and programmable.

Manual crimpers, like the P16HP, P16HPZ, and P16HAP, are simple, portable, and cost-effective. They’re great for small-scale operations or mobile work. They handle moderate sizes and are easy to maintain.

Electric workshop machines such as the P32, P32S, P32D, P32NC, and P140 provide higher crimping force10, faster cycles, and consistent results. They suit medium to large workshops, offering better precision for frequent and varied crimping jobs.

Some machines have programmable settings for repeated jobs, reducing the time lost in adjusting settings every time you switch hose sizes.

If you work in remote areas, portable models give flexibility. If you’re in a controlled shop environment, heavy-duty and programmable electric machines offer speed and repeatability.

| Type | Examples | Best Use |

|---|---|---|

| Manual | P16HP, P16HPZ, P16HAP | Low output, portable use |

| Electric | P32, P32S, P32D | Medium to high workshop output |

| Programmable | P32NC, P140 | High accuracy, repeated jobs |

How Much Crimping Force Do You Really Need?

Too little force and your crimp fails. Too much force and your hose is damaged. The right force is determined by what you crimp daily.

Choose the crimping force based on your largest hose size, number of reinforcement layers, and material hardness. Bigger hoses with more steel layers need greater force.

Manufacturers specify crimping force in tons or kilonewtons. A small portable machine might offer 100-200 kN, while large workshop models can exceed 3000 kN.

For hydraulic hoses, count the layers of steel wire reinforcement. A two-wire 1-inch hose needs far less force than a six-wire 2-inch hose. Oversizing your machine for your actual needs wastes money and energy, but undersizing causes operational failures.

Knowing the hardness of the material you crimp matters too. Aluminum fittings need less force than stainless steel. I’ve seen clients struggle because their machines weren’t sized for stainless applications.

A machine with adjustable force settings allows more flexibility if you handle a wide range of products.

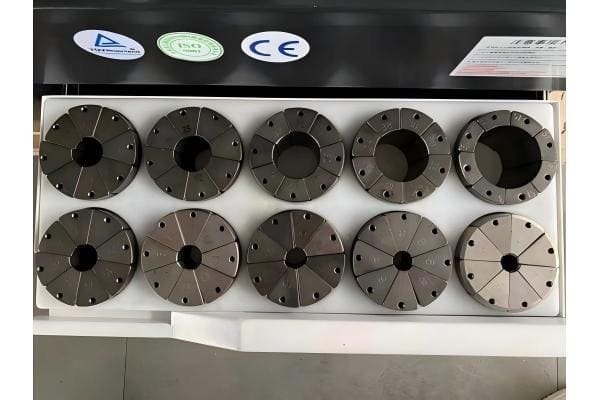

What Die Sets and Sizes Should You Prepare?

Your crimper’s flexibility depends on your die sets11. Without the right dies, your expensive machine can't do all your jobs.

Prepare dies for all hose sizes and fitting types you plan to crimp. Check they match your product range2 and confirm compatibility with the machine brand.

Die sets are sized to match specific hose diameters. Each die set applies pressure evenly over the fitting for a leak-free crimp. Using the wrong size damages the hose and fitting.

If you handle both small control hoses and large industrial hoses, you’ll need a wide die range. Some models allow quick-change dies, saving time during size changes.

Think ahead about special dies. If you crimp unique shapes or products with appearance requirements, you may need customized dies. Confirm the manufacturer can supply them.

I keep my dies labeled and organized. This prevents delay and avoids using the wrong set when switching between jobs.

Which Power Source and Portability Option Fits Your Work Best?

Power source choice affects where and how you can operate. Portability defines your flexibility.

Manual crimpers run without electricity, while electric models require stable voltage. Portable machines suit fieldwork, while heavy units stay in workshops for high-volume output.

Manual models excel in remote sites where electricity is unreliable. Electric models deliver speed, but you must check voltage compatibility and circuit breaker requirements.

Portability is critical for field repair service. Heavy-duty, floor-mounted machines excel for fixed industrial work but lack mobility.

Choose based on your operational environment. If you travel often, a compact manual or portable hydraulic crimper is best. For a busy workshop, invest in a full-size electric model.

What Safety and Calibration Features Should You Look For?

Safety features protect operators. Calibration ensures accuracy over time.

Look for emergency stop buttons, protective guards, pressure relief systems, and easy calibration access. These ensure safe use and consistent crimp quality.

In my experience, the emergency stop button has saved machines from damage more times than I can count. Protective guards keep hands away from moving dies. Pressure relief systems prevent over-crimping.

Calibration is often ignored until crimps become inconsistent. Regular calibration ensures the machine keeps your crimps within tolerance. Choose models that allow easy access for calibration adjustments.

Models with CE or ISO certification meet certain minimum safety requirements5—important if your customers demand compliance.

How Important Are After-Sales Service and Spare Parts?

Even the best machine will need service. Choosing a manufacturer with strong support is critical.

A good after-sales service team provides training, fast spare parts12 supply, and repair guidance. This minimizes downtime and keeps your operations running smoothly.

If your machine breaks during a busy season, fast parts delivery and repair help make a huge difference. High-end models with imported core parts often have easier local availability, making maintenance faster.

Ask if training is included with your purchase. Proper usage limits damage and extends machine life.

I’ve seen businesses stall for weeks because they chose suppliers without solid after-sales systems.

Which Model Fits Different Business Scales?

Not all operations require the same model. Scale dictates specifications.

Small businesses need manual or simple electric models, while large factories require high-force, programmable crimpers13 for efficiency and accuracy.

Small-scale work benefits from low-maintenance, affordable models. Large-scale production demands machines with high repeatability and faster cycle times.

Some mid-sized shops balance cost and speed by combining one heavy-duty workshop unit with portable crimpers for service calls.

How Can You Make the Final Decision with Confidence?

It’s easy to feel overwhelmed by all these considerations, but there’s a clear way forward.

Write down your product specs, daily output, workspace limits, budget, and required safety features. Then match these to machine capabilities for a perfect fit.

List all your work requirements, from smallest to largest hose size, reinforcement layers, material types, and crimp volumes. Note any certifications you must meet.

Compare this list to machine options. The right choice is the one that meets all requirements without excess cost or unused capacity.

When in doubt, I advise customers to consult suppliers with detailed information—they can suggest precise models that suit all operational needs.

Conclusion

Choosing the right hydraulic hose14 crimping machine means balancing product demands, budget, space, and service support for safe, efficient, and consistent performance.

Explore this link to find top-rated hydraulic hose crimpers that suit various needs and budgets. ↩

Understanding your product range is crucial; this link offers guidance on optimizing your crimping operations. ↩

Learn how to assess your daily output needs effectively to choose the right crimping machine. ↩

Explore options that fit your workspace constraints while maintaining efficiency. ↩

Safety is paramount; this resource outlines essential safety features for crimping machines. ↩

This resource provides insights on selecting the perfect crimping machine tailored to your specific requirements. ↩

Learn how to accurately estimate your daily crimping quantity for optimal machine selection. ↩

This link explains the benefits of manual crimpers for low-output and portable use. ↩

Learn about the advantages of electric crimpers for high-volume workshop applications. ↩

This resource helps you understand how to select the appropriate crimping force for your needs. ↩

Learn about the essential die sets required for effective crimping operations. ↩

This article discusses the importance of spare parts availability for minimizing downtime. ↩

Explore how programmable crimpers can enhance efficiency and accuracy in your operations. ↩

Explore the various types of hydraulic hoses and their compatibility with crimping machines. ↩