How to Maintain and Calibrate Your Hose Crimper?

Your hose crimper suddenly produces loose connections during a critical project. The downtime costs you money and damages your reputation. You need a reliable maintenance plan to prevent these failures.

Regular maintenance and proper calibration keep your hose crimper running smoothly for years. Clean weekly, lubricate moving parts, check hydraulic oil monthly, and calibrate annually to prevent crimping failures and ensure consistent quality.

I learned this lesson the hard way when a customer's project stopped because of a poorly maintained crimper. Since then, I always share these maintenance tips to help others avoid the same costly mistakes.

Why Is Regular Maintenance Important for a Hose Crimper?

Skipping maintenance means facing unexpected breakdowns when you need your equipment most. Your production stops, deadlines slip, and repair costs pile up quickly.

Regular maintenance prevents 80% of hose crimper failures. It extends equipment life, ensures consistent crimping quality, reduces downtime, and saves money on expensive emergency repairs and part replacements.

I see too many customers learn this lesson after their crimper fails during busy seasons. One customer in Texas told me his neglected machine broke down right before a major pipeline project. The emergency repair cost him three times more than regular maintenance would have.

Maintenance keeps all components working together smoothly. Moving parts stay lubricated and aligned. Hydraulic systems maintain proper pressure. Electrical components avoid premature failure. Dies stay sharp and precise. Without maintenance, small problems become big expensive ones.

When you maintain your crimper properly, you get consistent results every time. The crimps meet specifications. Hose assemblies don't leak. Your customers trust your work. Your reputation grows stronger.

I track maintenance records for all my customers. Those who follow maintenance schedules report 90% fewer breakdowns. Their crimpers last twice as long. They spend less money on parts and repairs over time.

How Often Should You Lubricate the Moving Parts?

Dry moving parts create friction, heat, and wear. The crimper becomes harder to operate. Components break sooner than expected. Your investment loses value quickly.

Lubricate moving parts weekly or after every 500 crimps. Apply lubricant on both sides of the crimping dies and the conical flanges. This prevents wear, reduces friction, and keeps the equipment operating smoothly for years.

Most operators forget about lubrication until something starts squeaking or sticking. By then, damage already happened. I tell customers to make lubrication part of their weekly routine.

Use the right grease for your crimper model. Check your manual for specifications. Different machines need different lubricants. Using wrong grease can damage seals and components. I recommend keeping manufacturer-approved grease in your workshop at all times.

Focus on high-movement areas first. The crimping head moves most during operation.These areas need attention every week without fail.

Apply grease until you see fresh lubricant appear. Old grease gets contaminated with dirt and metal particles. Fresh grease pushes out the contaminated material. Wipe away excess to prevent dirt from sticking.

Keep detailed records of lubrication dates. This helps you track maintenance intervals. Some busy shops crimp more than others. Count your crimps and lubricate based on usage, not just time.

What's the Correct Way to Clean a Hose Crimping Machine?

Dirt and debris damage precision components over time. Metal particles scratch moving parts. Oil residue attracts more contamination. Your crimper loses accuracy and reliability without proper cleaning.

Clean before and after each use session. Remove dust, oil residue, and metal particles with clean cloths. Never use water, solvents, or abrasives that can damage seals and electrical components.

I learned about cleaning the hard way when a customer's crimper developed expensive problems. He used brake cleaner to remove oil, which damaged the seals. The repair cost more than a year of proper cleaning supplies would have.

Pay attention to die areas where metal shavings collect. These particles can scratch dies and affect crimping quality.

Use clean, lint-free cloths for wiping surfaces. Avoid paper towels that leave fibers behind. Microfiber cloths work best for removing oil without scratching. Keep several cloths handy so you can use clean ones throughout the process.

Never spray water directly on the machine. Water damages electrical components and causes rust. If you need moisture, use a damp cloth on non-electrical surfaces only. Dry everything thoroughly before storing or using the crimper.

Clean dies carefully with appropriate brushes. Metal brushes can damage die surfaces. Use soft brushes instead. Keep dies properly oiled when not in use to prevent corrosion.

When Should You Replace the Hydraulic Oil and How to Choose the Right Type?

Contaminated hydraulic oil damages pumps, valves, and seals. Dirty oil reduces system pressure and affects crimping force. Your hose assemblies become unreliable and may fail under pressure.

Inspect hydraulic oil monthly and replace when dirty or deteriorated. Choose oil based on local climate and manufacturer specifications. Never overfill or underfill the reservoir to maintain proper system operation.

One customer in Alaska learned about oil selection the hard way. He used summer-grade oil during winter. The thick oil couldn't flow properly in cold weather. His crimper barely worked until spring when he switched to proper winter oil.

Check oil color and consistency monthly. Fresh hydraulic oil looks clear and flows smoothly. Contaminated oil appears dark, cloudy, or thick. If you see metal particles or water in the oil, replace it immediately. Contaminated oil causes expensive damage throughout the system.

Climate affects oil choice significantly. Cold areas need thinner oil that flows at low temperatures. Hot climates require thicker oil that doesn't break down from heat. Consult your manufacturer for specific recommendations based on your location.

Fill the reservoir to the correct level marked on the dipstick or sight gauge. Overfilling causes oil to foam and lose pressure. Underfilling allows air into the system, which also reduces pressure and causes erratic operation.

Dispose of used oil properly according to local regulations. Most auto parts stores accept used hydraulic oil for recycling. Never dump oil on the ground or in storm drains. Environmental violations carry heavy fines and damage your business reputation.

What Key Points Should You Check During Routine Inspection?

Hidden problems grow into expensive failures without regular inspection. Worn dies produce bad crimps. Loose electrical connections cause erratic operation. Small issues become big problems quickly.

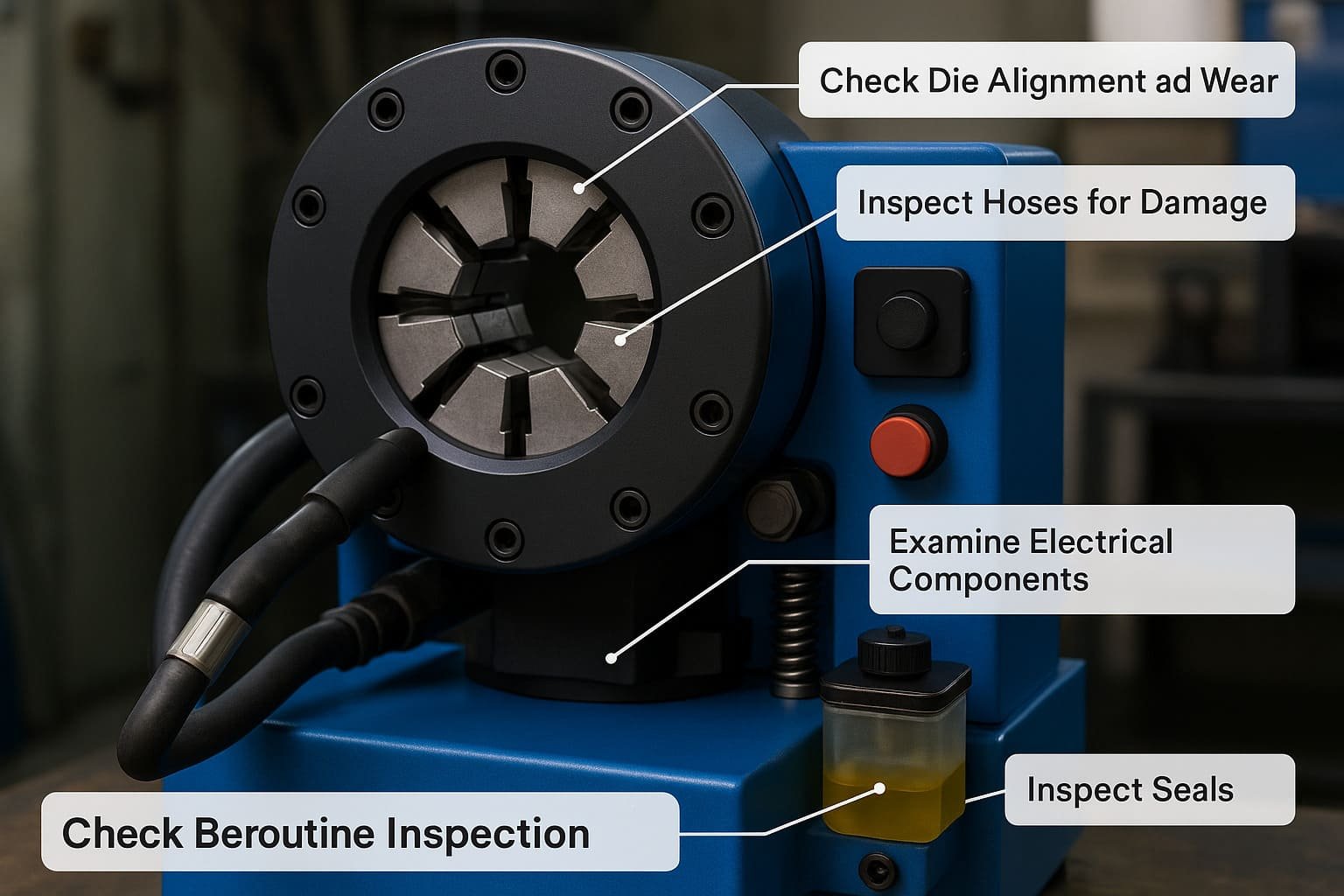

Check die alignment and wear, inspect hoses for damage, examine electrical components for aging, verify spring condition, monitor system pressure, and inspect seals annually for leaks or deterioration.

I created this inspection checklist after seeing too many preventable failures. One customer's die cracked because he never checked for wear. The broken die damaged expensive fittings and caused a major project delay.

| Inspection Point | Check Frequency | Warning Signs | Action Needed |

|---|---|---|---|

| Die Alignment | Weekly | Uneven crimps, off-center marks | Realign or replace dies |

| Die Wear | Monthly | Rounded edges, visible damage | Replace worn dies |

| Hose Condition | Before each use | Cracks, cuts, oil contamination | Replace damaged hoses |

| Electrical Components | Monthly | Corrosion, loose connections, burning smell | Repair or replace |

| Springs | Monthly | Deformation, cracks, weak tension | Replace damaged springs |

| System Pressure | Weekly | Pressure drops, inconsistent crimps | Adjust under manufacturer guidance |

| Seals | Annually | Oil leaks, hardening, cracking | Replace deteriorated seals |

Dies need the most attention because they directly affect crimp quality. Look for chips, cracks, or rounded edges. Measure die diameter if you have precision tools. Worn dies produce loose or inconsistent crimps that fail under pressure.

Electrical problems start small but grow dangerous quickly. Check all connections for tightness and corrosion. Look for burned or discolored components. Smell for burning odors that indicate overheating. Replace questionable parts before they fail completely.

System pressure affects every crimp your machine makes. Too low pressure creates loose connections. Too high pressure can damage hoses and fittings. Only adjust pressure following manufacturer instructions. Never exceed rated system pressure limits.

How Should You Store the Hose Crimper When Not in Use?

Improper storage leads to corrosion, contamination, and component damage. Dust enters precision mechanisms. Moisture causes rust. Temperature changes affect seals and lubricants.

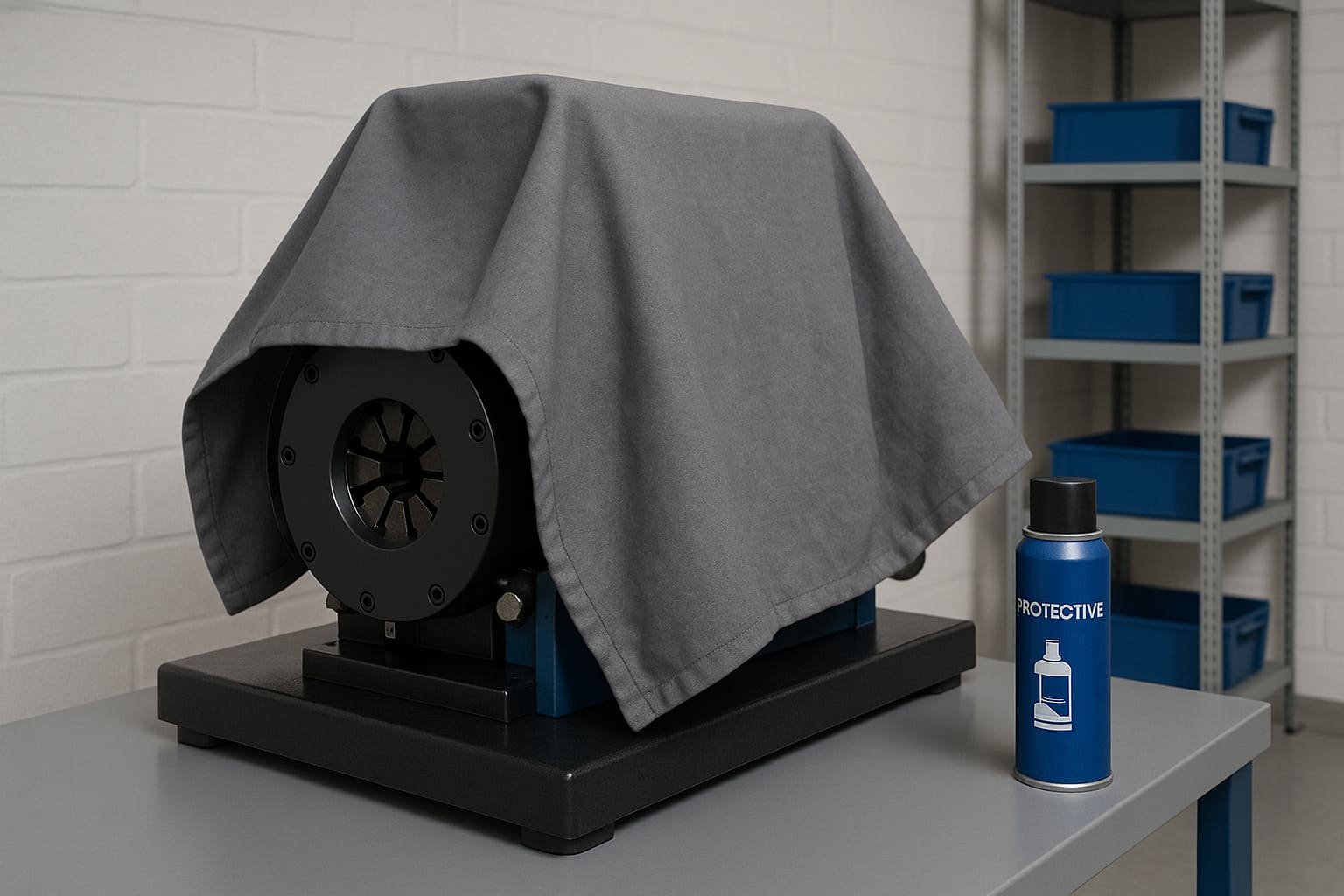

Cover the machine to prevent dust entry. Store in clean, dry environments. Apply anti-rust protection for long-term storage. Check periodically to ensure good working condition is maintained.

A customer in Florida learned about storage the expensive way. He left his crimper uncovered in a humid warehouse. After six months, rust damaged the dies and contamination clogged the hydraulic system. The cleanup and repair cost more than proper storage would have.

Use fitted covers or plastic sheeting to protect against dust. Dust seems harmless but gets into moving parts and causes wear. Cover all openings where dust can enter. Pay special attention to die areas and hydraulic reservoirs.

Control humidity in storage areas when possible. High humidity causes rust on metal surfaces. Use dehumidifiers in damp locations. Silica gel packets help control moisture in smaller enclosed spaces.

For extended storage beyond three months, apply protective coatings to exposed metal surfaces. Light machine oil or specialized rust preventatives work well. Don't forget internal components like dies and guide rails.

Check stored equipment monthly even when not in use. Look for signs of moisture, pest intrusion, or component deterioration. Run the machine briefly to circulate fluids and exercise moving parts. This prevents seals from drying out and keeps everything working smoothly.

Why Should Operators Receive Professional Training Before Use?

Untrained operators cause expensive damage through improper use. They choose wrong settings, ignore warning signs, and create safety hazards. Poor technique produces bad crimps that fail in service.

Trained operators prevent equipment damage, ensure consistent quality, maintain safety standards, and recognize problems early. Professional training reduces accidents, extends equipment life, and improves crimping results.

I see the difference training makes every day. Trained operators produce better crimps, maintain equipment properly, and avoid costly mistakes. Untrained operators often damage equipment within the first month of use.

Proper technique starts with understanding how the machine works. Operators need to know about hydraulic pressure, die selection, and crimping sequences. They must understand how their actions affect the final product quality.

Safety training prevents accidents that hurt people and damage equipment. Hydraulic crimpers generate tremendous force. Improper handling can cause serious injuries. Trained operators follow safety procedures automatically.

When problems occur, trained operators know how to respond appropriately. They document issues properly for manufacturers or technicians. They avoid making problems worse through incorrect troubleshooting attempts.

I recommend sending operators to manufacturer training programs when available. Video training helps but hands-on instruction works better. Keep training records for insurance and liability purposes.

How Do You Calibrate a Hose Crimping Machine Correctly?

Calibration drift causes crimps that don't meet specifications. Loose connections leak under pressure. Tight crimps damage hose structures. Your reputation suffers when assemblies fail in service.

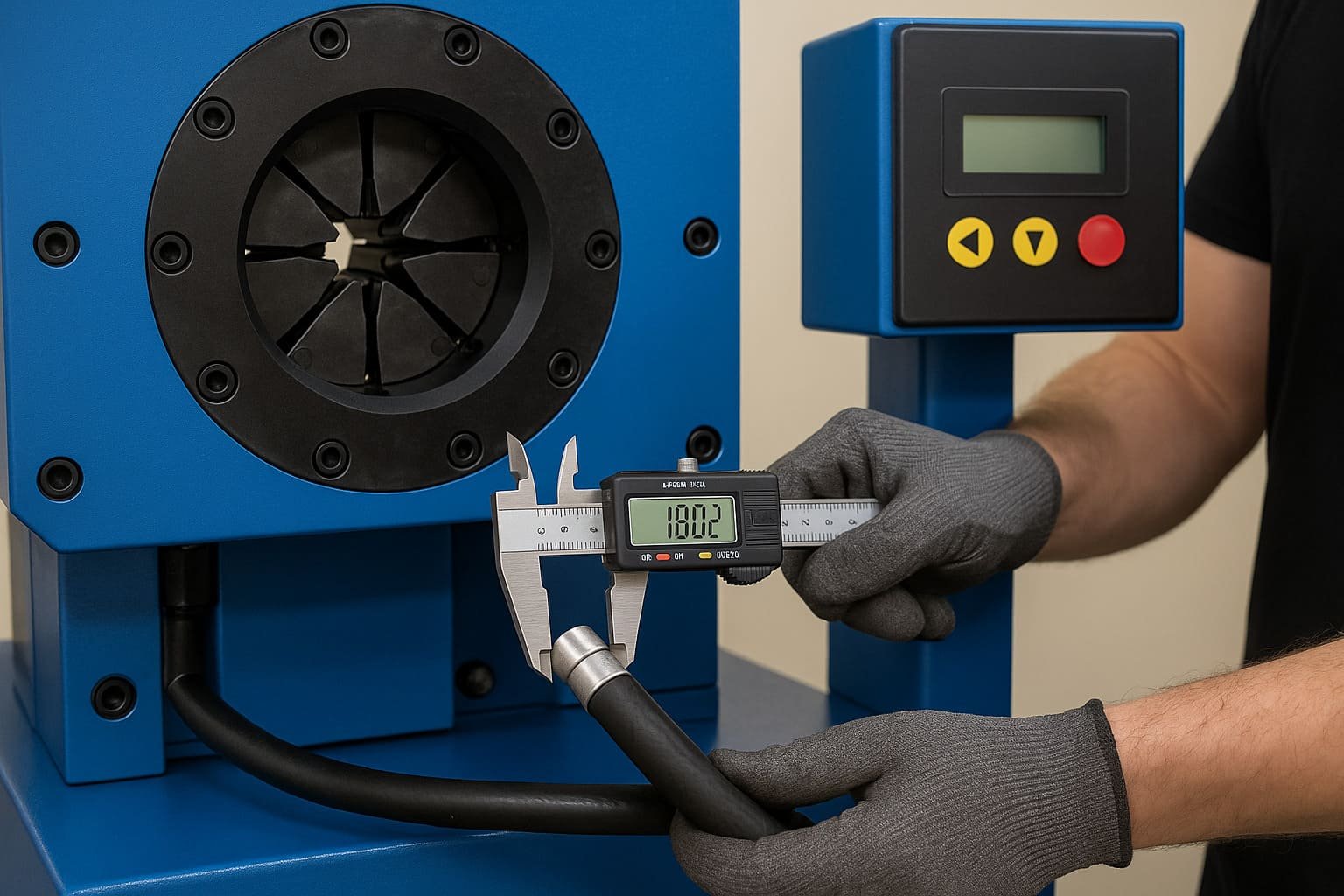

Calibrate annually or when crimps measure outside specifications. Use proper measuring tools, follow manufacturer procedures, and document results. Regular calibration ensures consistent crimp dimensions and prevents quality problems.

Calibration keeps your crimper producing accurate results year after year. I track calibration records for customers and see clear quality improvements when they maintain proper calibration schedules.

Start with the right measuring tools. Digital calipers work better than mechanical ones for precision measurements. Micrometers provide even better accuracy for critical applications. Keep measuring tools calibrated and properly maintained.

Follow manufacturer calibration procedures exactly. Each machine design requires specific steps and sequences. Don't skip steps or make shortcuts. Document each measurement and adjustment you make during the process.

Test calibration with sample crimps using known good dies and fittings. Measure finished crimps and compare to specifications. Make small adjustments as needed. Retest after each adjustment to verify improvement.

Keep detailed calibration records including dates, measurements, adjustments, and operator information. These records help track machine performance over time and provide documentation for quality certifications.

What Can You Learn from Real-World Calibration Cases?

Real customer experiences teach valuable lessons about calibration timing and techniques. Success stories show proper procedures work. Problem cases reveal common mistakes to avoid.

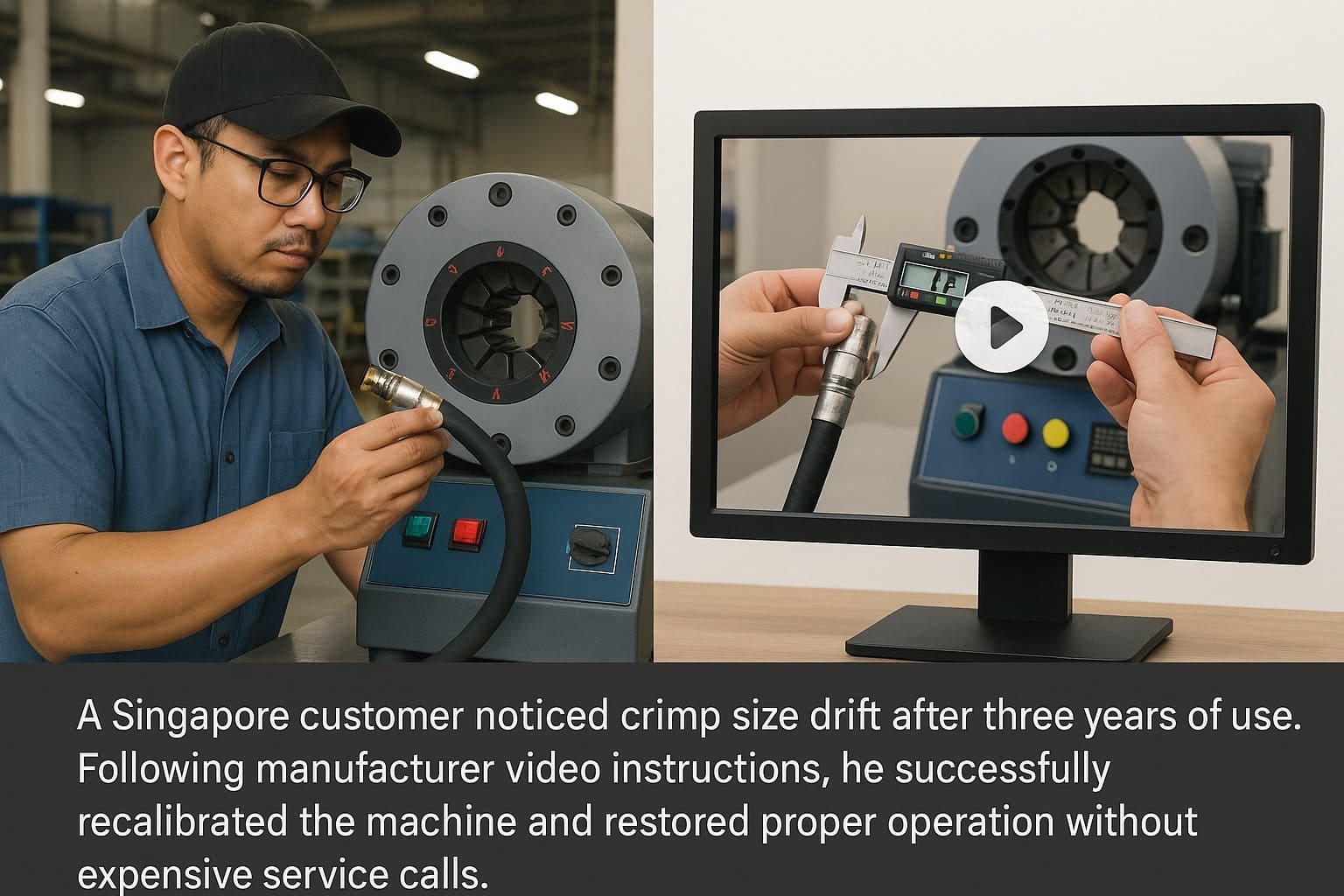

A Singapore customer noticed crimp size drift after three years of use. Following manufacturer video instructions, he successfully recalibrated the machine and restored proper operation without expensive service calls.

This Singapore case shows how calibration drift happens gradually over time. The customer used his crimper regularly for three years without problems. Then he noticed finished assemblies didn't meet specifications like they used to.

Instead of ignoring the problem or guessing at solutions, he contacted us for guidance. We provided the manufacturer's calibration video and talked him through the process step by step. He had the right measuring tools and followed instructions carefully.

The calibration process took about two hours including testing and verification. His crimps returned to proper specifications immediately. He avoided an expensive service call and learned valuable skills for future maintenance.

This case highlights several important points. First, calibration drift is normal over time and use. Second, proper documentation helps identify when calibration is needed. Third, manufacturer resources provide the best guidance for calibration procedures.

Another customer in Germany ignored calibration for five years until major problems developed. By then, multiple components needed replacement because improper crimps stressed the entire system. Early calibration would have prevented expensive repairs.

How Can Proper Maintenance Prevent Crimping Failures?

Crimping failures damage your reputation, waste materials, and create safety hazards. Proper maintenance prevents most failures by keeping all systems operating within specifications.

Regular maintenance prevents 90% of crimping failures through lubrication, cleaning, inspection, and calibration. Well-maintained machines produce consistent results, last longer, and avoid expensive emergency repairs.

I track failure rates for customers who follow maintenance schedules versus those who don't. The difference is dramatic. Well-maintained machines rarely fail unexpectedly. Neglected machines break down regularly and cost much more to operate.

Maintenance prevents failures by addressing problems before they become serious. Weekly lubrication prevents wear that leads to misalignment. Monthly cleaning removes contamination that damages seals. Regular inspection catches worn parts before they break.

Proper hydraulic oil maintenance keeps the entire system operating smoothly. Clean oil maintains pressure and prevents component damage. Contaminated oil causes erratic operation and premature failures throughout the hydraulic system.

Calibration maintenance ensures every crimp meets specifications. Properly calibrated machines don't produce loose connections that leak or tight crimps that damage hoses. Your assemblies work reliably in service for years.

The cost of maintenance is small compared to failure costs. Regular maintenance might cost a few hundred dollars per year. A single major failure can cost thousands in repairs plus lost production time.

Conclusion

Proper maintenance and calibration keep your hose crimper running reliably for years. Follow these procedures consistently to prevent failures, ensure quality, and protect your investment.