How to choose air conditioning hose crimping machine?

Are you struggling to find the right A/C hose crimping machine1 for your business? Wrong choice can cost you thousands and slow down your work.

Choosing the right A/C hose crimping machine depends on your daily volume, budget, and specific crimping needs. Manual machines work for small repairs, electrical units handle medium capacity, and hydraulic machines2 suit high-volume operations with precise crimping requirements.

I learned this lesson the hard way when I first started at CYT-HYDRAULIC. A customer bought the wrong machine type and came back frustrated after just two weeks. That experience taught me how crucial proper selection is.

What is the a/c hose crimping machine?

Do you know what makes A/C systems work without leaks? The answer lies in proper hose crimping technology.

An A/C hose crimping machine permanently joins hoses and fittings by compressing a ferrule around the connection point. This creates a leak-proof seal essential for air conditioning systems to maintain proper pressure and refrigerant flow.

These machines work by applying controlled pressure to compress metal ferrules or sleeves around the connection between A/C hoses and fittings. The crimping process deforms the ferrule to create a mechanical seal that prevents refrigerant leaks.

I remember when one of my customers tried to use regular hydraulic crimping dies for A/C work. The results were terrible - leaks everywhere and damaged fittings. A/C applications3 need specialized dies designed for the specific ferrule shapes and materials used in automotive air conditioning systems.

The crimping force4 must be precise. Too little pressure creates weak connections that leak under system pressure. Too much force damages the hose or fitting, also causing leaks. This is why dedicated A/C crimping machines have pressure control5s specifically calibrated for refrigeration applications.

Key Components of A/C Crimping Systems

| Component | Function | Importance |

|---|---|---|

| Dies | Shape the ferrule during crimping | Critical for proper seal formation |

| Pressure Control | Regulates crimping force | Prevents over/under crimping |

| Hose Positioning | Holds assembly during crimp | Ensures accurate placement |

| Ferrule Guide | Aligns components correctly | Reduces setup errors |

How many types the a/c hose crimping machine has?

Are you confused by all the different A/C crimping machine options available? Let me break down the three main types for you.

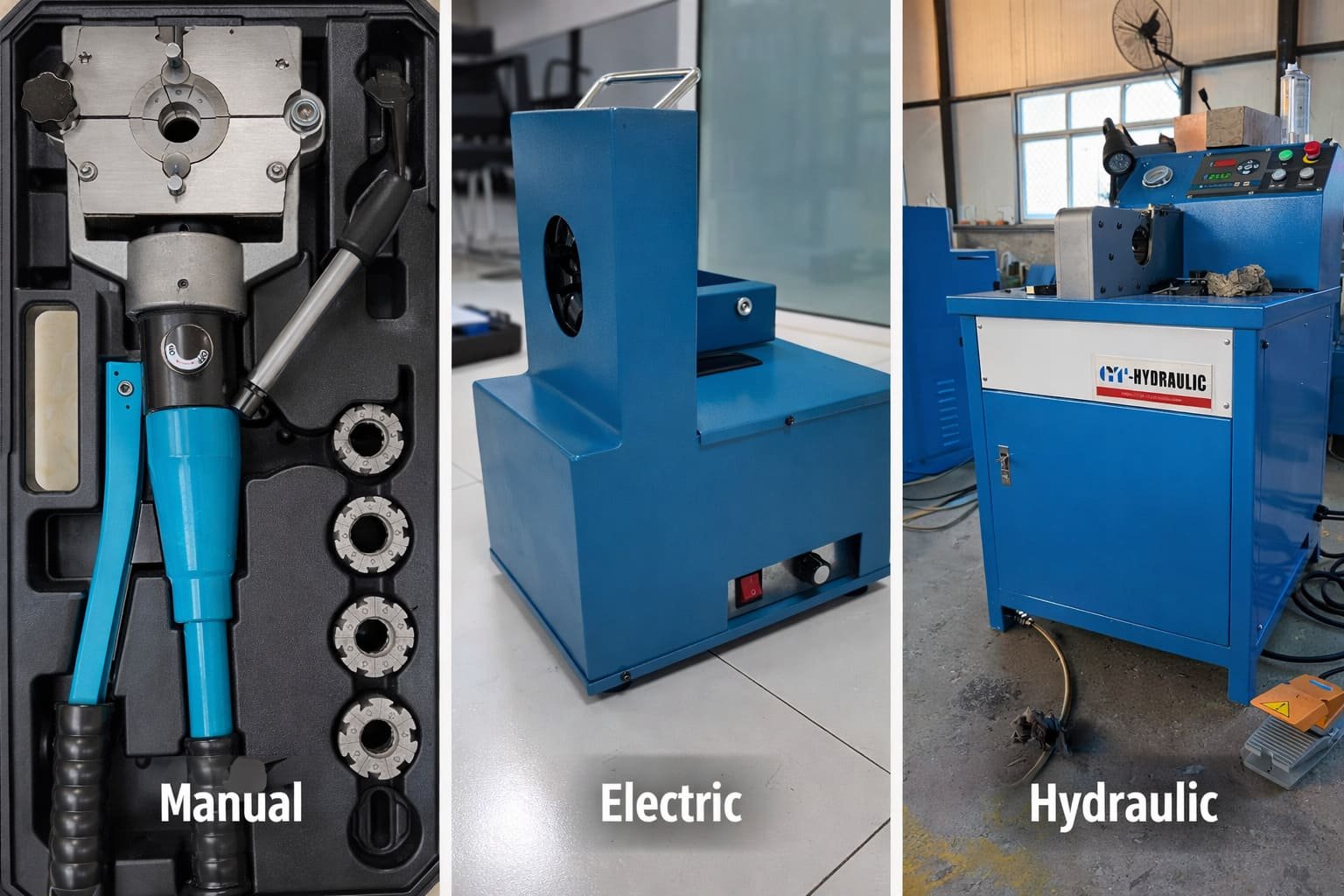

A/C hose crimping machines come in three main types: manual for portable repairs, electrical for medium-volume shops, and hydraulic for high-capacity operations. Each type serves different business needs and volume requirements.

After years in this industry, I've seen businesses make expensive mistakes by choosing the wrong type. Here's what you need to know about each option.

Manual A/C Hose Crimping Machines

Manual machines are the simplest option. You operate them by hand, making them perfect for mobile repair services or low-volume work. These units are lightweight and portable, so you can take them to job sites easily.

The main advantage is cost. Manual crimpers typically cost much less than powered versions. They don't need electricity, so you can use them anywhere. I often recommend these to technicians just starting their mobile A/C repair business.

However, manual operation limits your speed and can tire you out during busy days. The crimping force depends on your physical strength, which can affect consistency. For occasional repairs or emergency work, they're excellent. For daily production, you might want something more powerful.

Electrical A/C Hose Crimping Machines

Electrical machines offer the perfect middle ground. They run on standard 220V power and typically include a foot pedal for hands-free operation. This setup lets you position the hose assembly with both hands while controlling the crimp with your foot.

One major benefit is the adjustable pressure system. You can set the exact crimping force needed for different hose sizes using just one set of dies. This saves money on tooling and reduces setup time between jobs.

These machines work well for automotive shops handling moderate A/C repair volumes. The consistent electrical power delivers uniform crimping force, improving quality compared to manual operation. The foot pedal control keeps your hands free to guide the hose assembly.

Hydraulic A/C Hose Crimping Machines

Hydraulic units represent the top tier for serious production work. They deliver the highest crimping force with exceptional accuracy and consistency. These machines typically feature side-feeding designs that work perfectly with elbow fittings and complex assemblies.

The automatic operation speeds up production significantly. You simply load the assembly, press a button, and the machine handles the rest. This consistency reduces waste and improves quality control in high-volume environments.

Hydraulic machines excel at crimping thick-walled hoses and hard materials that would challenge manual or electrical units. The stable crimping force ensures reliable connections even with demanding applications.

| Machine Type | Best For | Advantages | Limitations |

|---|---|---|---|

| Manual | Mobile repair, low volume | Portable, low cost, no power needed | Slower, requires physical effort |

| Electrical | Medium volume shops | Consistent force, foot pedal control | Needs power source, moderate speed |

| Hydraulic | High volume production | Fastest, most accurate, handles tough jobs | Highest cost, requires maintenance |

What factors need to be considered?

What separates successful A/C hose assembly from costly failures? The answer lies in understanding the critical factors that affect your crimping results.

Key factors include hose layer count6 and fitting materials7, required crimping force and accuracy, daily production capacity8, power requirements9, custom die specifications10, your budget, and available after-sales support from the manufacturer.

I've helped hundreds of customers avoid expensive mistakes by focusing on these essential factors. Let me share what really matters.

Hose and Fitting Specifications

The thickness of your A/C hose directly affects machine requirements. Four-layer hoses need less crimping force than seven-layer versions. I always ask customers about their typical hose specifications before recommending equipment.

Fitting materials make a huge difference too. Aluminum fittings require gentler crimping than steel versions to avoid damage. Steel fittings need more force but can handle higher pressures. Your machine must match these requirements.

Crimping Force and Accuracy Requirements

Crimping force determines whether your connections will hold under system pressure. Too little force creates leaks. Too much force damages components. The right machine provides consistent force within tight tolerances.

Accuracy becomes critical with expensive A/C components. A few thousandths of an inch difference in crimp diameter can mean the difference between a perfect seal and a costly comeback. Higher-end machines offer better repeatability.

Production Capacity Needs

Your daily volume determines which machine type makes financial sense. If you're doing five assemblies per day, a manual unit works fine. If you need fifty assemblies daily, hydraulic machines pay for themselves through speed and consistency.

I learned this when a customer bought a manual machine for high-volume work. Within three months, they upgraded to hydraulic because the manual unit couldn't keep up with demand.

Power Source and Control Options

Consider your shop's electrical setup. Manual machines need no power. Electrical units typically require 220V single-phase power. Hydraulic machines might need three-phase power for optimal performance.

Control systems vary from simple on/off switches to programmable pressure controllers. More sophisticated controls cost more but offer better repeatability and easier operation.

Custom Die Requirements

Dies must match your specific applications exactly. Factors include:

Hose Specifications:

- Inner diameter range

- Outer diameter variations

- Wall thickness and layer count

Ferrule Requirements:

- Inner and outer diameter

- Length and wall thickness

- Material type (aluminum, steel, brass)

Fitting Specifications:

- Material and hardness

- Size range and thread types

- Special shapes or angles

Final Assembly Appearance:

- Crimp diameter accuracy

- Surface finish requirements

- Length tolerances

Budget Considerations

Machine cost is just the starting point. Consider ongoing expenses like die sets, maintenance, and training. A cheaper machine with expensive dies might cost more long-term than a pricier unit with affordable tooling.

Factor in productivity gains too. A faster machine might justify its higher cost through increased output and reduced labor time per assembly.

After-Sales Service Quality

Machine downtime costs money and frustrates customers. Choose suppliers who offer prompt technical support, readily available parts, and comprehensive training programs.

At CYT-HYDRAULIC, we've built our reputation on responsive service. When customers have problems, they need solutions quickly, not excuses or delays.

Conclusion

Choose your A/C crimping machine based on volume needs, hose specifications, and long-term business goals for optimal performance and profitability.

Understanding the function of an A/C hose crimping machine is crucial for making informed purchasing decisions. ↩

Discover why hydraulic machines are preferred for high-volume production and their advantages. ↩

Understanding A/C applications helps in selecting the right machine for your needs. ↩

Understanding crimping force is essential for ensuring leak-proof connections in A/C systems. ↩

Explore the significance of pressure control in achieving accurate and reliable crimping. ↩

Understanding hose layer count is vital for choosing the right crimping machine. ↩

Learn about different fitting materials and their impact on crimping performance. ↩

Assessing production capacity is crucial for selecting the right machine for your business. ↩

Understanding power requirements helps ensure compatibility with your shop's electrical setup. ↩

Explore the importance of custom dies in achieving precise crimping results. ↩