A wrong choice in a hose cutting machine1 can lead to poor cuts, hose damage, and wasted money. Many buyers make mistakes because they overlook small but critical details.

To choose the right hose cutting machine, first understand your hose type and working scenario2. Then check cutting blade quality3, safety features4, and total cost of ownership5 before buying.

Selecting the right hose cutting machine can often feel complicated, especially for those just starting in hydraulic repair or hose production. I’ve seen many customers buy machines that fail to match their hose types or production needs. That’s why I decided to share this simple and practical guide, based on years of helping clients find the best fit.

How does hose type affect your choice of cutting machine?

The hose type determines what kind of cutting machine you actually need. Many people start with the wrong assumption that one machine fits all hoses.

Always match your machine to your hose type — whether hydraulic, industrial, thermoplastic, or metal — and confirm the diameter range and reinforcement layers before buying.

The best way to begin is to identify your hose type and size. Hydraulic hoses, for example, are often reinforced with steel wire layers that require strong motor power and precise blades. Industrial hoses may have softer walls, and thermoplastic hoses6 burn easily when cut at high speed. I often ask customers if their hydraulic hoses7 are from 1/4” to 2” or if they handle larger 3” hoses. The wire layers—two, four, or six—also change the cutting resistance and machine requirements.

| Hose Type | Typical Diameter | Reinforcement Layers | Recommended Cutting Method |

|---|---|---|---|

| Hydraulic Hose | 1/4”–3” | 2–6 steel layers | Electrical cutting, high-speed steel blade |

| Industrial Hose | Up to 3” | Textile layers | Moderate speed cutting |

| Thermoplastic Hose | 1/4”–2” | Fiber or plastic reinforcements | Low temperature cutting |

| Metal Hose | Variable | Metal braided | Specialized blade with strong torque |

Choosing the right combination ensures clean cuts, less deformation, and longer machine life. Mismatched machines can twist or burn hose ends, leading to leaks after assembly.

Which type of cutting machine fits your working scenario2 best?

Different working environments require different power setups. Many buyers forget that location matters as much as machine specs.

For workshop use, an electrical hose cutting machine is best; for outdoor service or mobile repairs, choose a 12V or 24V version for easy power access.

When I visit customer sites, I notice how many use electrical cutting machines in their repair shops. These models handle most hydraulic hoses7 smoothly and safely. However, when I work with customers who repair hydraulic systems outdoors—on construction sites or trucks—I always recommend portable 12V or 24V models. The power source is the key factor that ensures continuous operation and efficient workflow. If you plan high production volume8, go for a stable electric model with strong cooling and dust control systems. For smaller or field-scale repairs, portability wins every time.

| Working Scenario | Recommended Machine Type | Power Source | Typical Use Case |

|---|---|---|---|

| Hydraulic repair shop | Electrical cutting machine | 220V AC | Medium to high production |

| Outdoor repair service | Portable cutting machine | 12V / 24V DC | Field service, onsite repair |

| Distributor workshop | Standard electric model | 220V AC | Daily production, hose assembly |

| Large manufacturer | High-performance system | Three-phase | Continuous production line |

Matching your working scenario helps you avoid power mismatch problems, ensures smooth cutting, and reduces downtime.

Why is blade quality the key to cutting performance?

Blades often seem like simple consumables, but their material and design heavily influence the cutting surface, hose deformation, and cost efficiency.

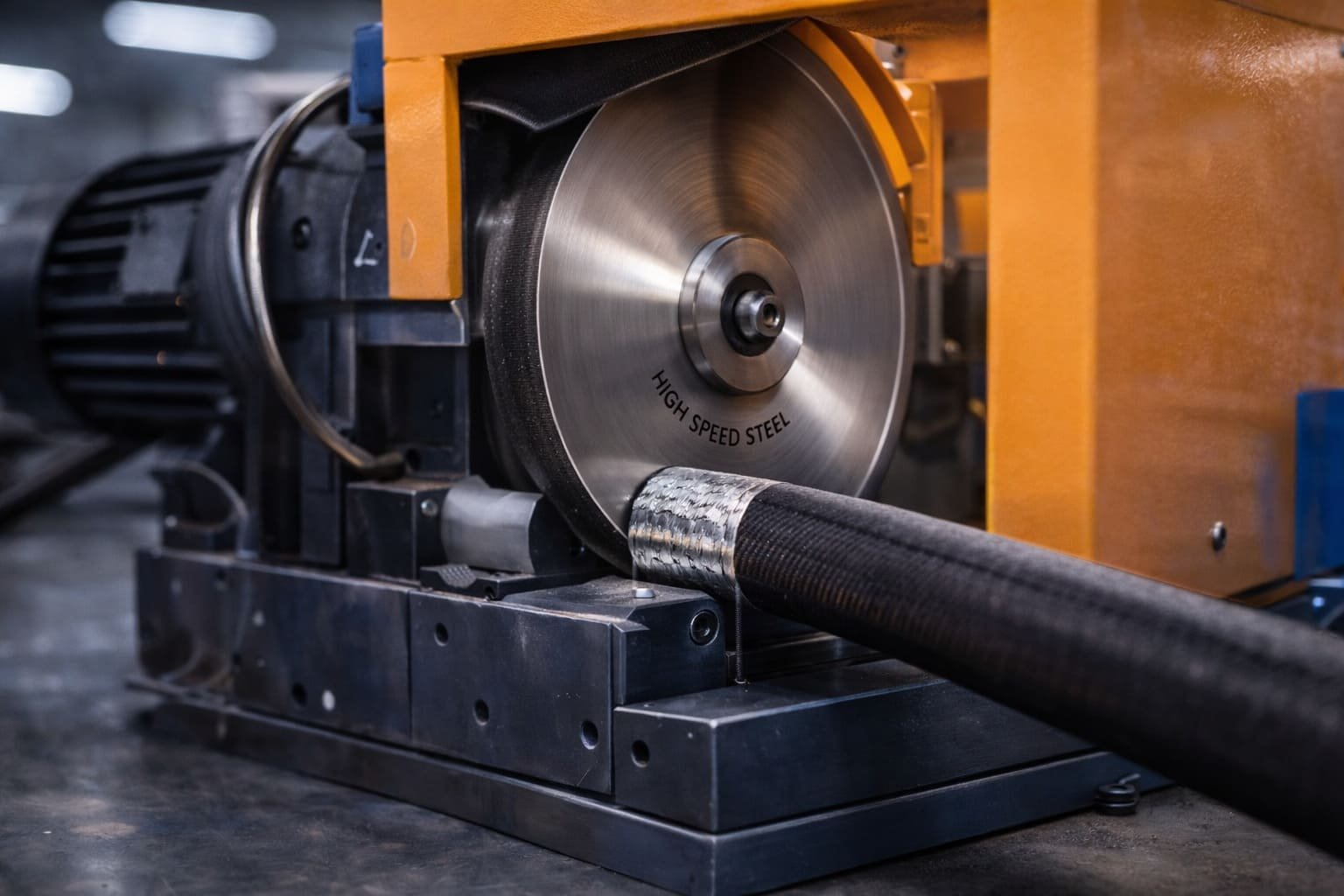

Choose high-speed steel blades9 for the cleanest cuts, minimal hose distortion, and longer lifespan — they reduce smoke and save money over time.

I always remind my customers that the blade determines cutting quality. Poor blades create rough edges and deform the hose, forcing costly rework. High-speed steel blades stay sharper longer and generate less smoke, especially in intensive workshop use. They not only cut faster but also protect the hose’s internal structure. Over time, the blade replacement schedule directly affects your total cost. Investing in high-speed steel blades means saving on labor time, minimizing waste, and maintaining consistent performance.

| Blade Material | Cutting Quality | Durability | Smoke/Dust Level | Recommended Use |

|---|---|---|---|---|

| High-speed steel | Excellent | Long life | Low | Hydraulic hose cutting |

| Standard steel | Average | Medium | Medium | Industrial hose cutting |

| Hard alloy | High precision | Longest | Low | Metal hose cutting |

| Carbide-tipped | Fine | Long | Low | Mixed materials |

A well-chosen blade can make your cutting machine feel brand new even after years of use.

What safety features should a professional hose cutting machine include?

Safety features often separate a hobby-grade machine from a professional one. Many users overlook them until accidents happen.

A professional cutting machine must include a fully enclosed blade guard, an emergency stop button10, a stable clamping system11, and dust/smoke control to protect the operator.

I once saw a setup where the cutting area was open with no guard protection, and the operator’s glove caught in the hose. That’s when I realized how essential these safety features are. Fully enclosed blade guards prevent contact with moving parts, while an emergency stop button allows immediate shutdown. A strong clamping system stabilizes the hose, ensuring straight, smooth cuts. Smoke and dust control systems protect your lungs and maintain a clean workspace. These may look like small additions, but they define a professional-grade machine and help your team work with confidence.

| Safety Feature | Purpose | Common Issues Without It |

|---|---|---|

| Fully enclosed blade guard | Prevent accidental blade contact | Injury risk |

| Emergency stop button | Quick shutdown in emergencies | Slow reaction during incidents |

| Stable clamping system | Keeps hose fixed during cutting | Slanted or rough cuts |

| No-smoke/no-dust system | Maintains clean air and visibility | Health hazard, dirty workspace |

Why should you think about total cost, not just machine price?

Many buyers focus only on price and ignore downtime and after-sales costs. This mistake often leads to disappointment and higher long-term expense.

Consider blade lifespan12, maintenance frequency13, downtime cost, and spare parts availability14 — the total cost tells the real story of machine value.

When helping new buyers, I always ask them to think beyond the machine’s price tag. A cheap machine might save money today, but higher maintenance, lost production time, and poor support often cost more in the long run. Reliable machines come with stronger blades, stable performance, and available spare parts. I sometimes show customers a simple calculation that includes blade changes, downtime, and service responses — it usually changes their buying perspective completely.

| Cost Factor | Description | Long-Term Effect |

|---|---|---|

| Blade lifespan | Frequency of replacement | Impacts operating cost |

| Maintenance frequency | Need for servicing | Affects uptime reliability |

| Downtime cost | Lost time during repair | Reduces productivity |

| Spare parts support | Availability from supplier | Determines repair speed |

Your total cost value shows how efficient and profitable your cutting operation can be.

Why should you choose a supplier who understands hydraulic applications?

A supplier who knows your hose application ensures your machine fits your actual work, rather than just meeting general specs.

Choose a supplier who asks about your hose type, understands your real working conditions, and provides complete technical data and spare parts support.

This point comes from my own experience. I often receive messages from customers who bought machines from general tool suppliers but received wrong models. A supplier familiar with hydraulic applications knows how hoses behave under pressure and tension, and will suggest the right cutting method15. They offer clear data on motor power, cutting speed, and compatibility, making your decision simple. Reliable suppliers also maintain spare parts availability, which matters most after months of operation. When something breaks, you want fast support — not long waiting times.

| Supplier Criteria | Key Evaluation Point | Benefit to Buyer |

|---|---|---|

| Industry experience | Understands hydraulic applications | Tailored machine recommendations |

| Technical data transparency | Clear specs and standards | Informed buying decisions |

| Spare parts support | Easy to access after purchase | Short repair downtime |

| After-sales assistance | Ongoing communication and advice | Strong long-term partnership |

Finding a supplier who knows your hydraulic needs builds trust and ensures that your machine investment pays off for years.

Conclusion

Choosing the right hose cutting machine means matching hose type, cutting environment, blade quality, and safety features — think long-term value, not short-term cost.

Explore this link to find expert reviews and comparisons of various hose cutting machines tailored to your specific requirements. ↩

Discover how different working environments influence the selection of hose cutting machines. ↩

Learn about the importance of cutting blade quality and how it impacts efficiency and cost in hose cutting operations. ↩

Discover essential safety features that can protect operators and enhance the safety of hose cutting processes. ↩

Understand the long-term costs associated with hose cutting machines beyond the initial purchase price. ↩

Gain insights into thermoplastic hoses and their unique cutting needs for better machine selection. ↩

Explore this resource to learn about various hydraulic hoses and how they influence cutting machine selection. ↩

Understand how your production volume affects the choice of hose cutting machines for efficiency. ↩

Explore the advantages of high-speed steel blades and their impact on cutting performance and longevity. ↩

Understand the critical role of emergency stop buttons in ensuring operator safety during cutting operations. ↩

Learn how a reliable clamping system enhances cutting precision and reduces waste in hose cutting. ↩

Explore the factors that influence blade lifespan and how to maximize the efficiency of your cutting operations. ↩

Find out the recommended maintenance schedules for hose cutting machines to ensure optimal performance. ↩

Learn why having access to spare parts is crucial for minimizing downtime and maintaining productivity. ↩

Explore various cutting methods and their suitability for different hose types and applications. ↩